超声波金属焊接技术是1950年我公司航空项目科研中发现,SONOBOND在1960年拿到了全世界第一个专利。

“I’malwayslookingoutforthemostadvanced,innovativeprocessesinthemarket.Ihavenoproblemsgivingreferencesonyourmachinesandwork,andJorgecanevenseethemachinesworkinghereoratPauloHora’splant.”

RuiPedroCoelho,GEEnergyManagement通用公司葡萄牙分公司

VilaNovadeGalia,Portugal

RuiPedro.Coelho@ge.com,351-223-746024

CurtReynolds,DirectorofManufacturingJ&M加拿大分公司

J&MProducts,SanFernando,CA

“Sonobondtechnologyisquickanddependable.Itdeliversrepeatablyexcellentwelds.Inaddition,Sonobondprovidesfast,reliabletechnicalsupport.I’dratetheirperformanceaspracticallya‘10.’Youcan’tdobetterthanthat!”

TomCrumpton,ProductionSuperintendent美国CornellDubilier电气集团

CornellDubilier,Liberty,SC

AdditionalRecommendationsAvailableUponRequest

50YearsofLeadership

WidestSelectionofFilterAssemblyMachines

ViewtheFilterAssemblyDemoVideo

Readourarticleoncapacitorassembly

ViewtheMetalWeldingDemoVideo

HagaclicporfavoraquíparaEspaolInnovation,performance,andservicemakeSonobondthesmartchoiceforultrasonicwelders.In1960,Sonobond(thenknownasAeroprojects)receivedthefirstpatentforultrasonicmetalwelding.Sincethen,thecompanyhasreceivedmorethan150additionalpatents.Theseincludenotonlymetalwelders,butcustom-engineeredultrasonicbondersofalltypes.TodaySonobondproducesequipmentfor:

UltrasonicMetalwelding

UltrasonicTextilebonding

UltrasonicPlasticbonding

UltrasonicNonwovenbonding

UltrasonicFilterassembly

UltrasonicPhotovoltaiccellassembly

Ultrasonicbodyarmorassembly

UltrasonicBatteryassembly

AWideVarietyofApplications

Sonobond'sultrasonicmachineryisusedbycompaniesaroundtheworld.Itsstate-of-the-artproductlineincludesthefollowing:

TheSonoWeld1600microprocessor-controlledwelderforaluminumwelding,weldingtin-coatedwires,andbatteryassembly.

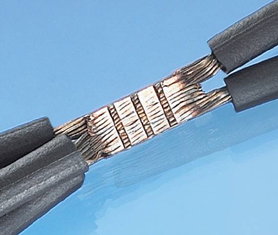

TheSpliceRiteWireSplicerforfast,efficientwireharnessassembly.

ThepowerfulWeldMasterforsuperiorspotwelding.

SeamMasterHighProfile,PlungeBonder,andRingMasterbondersforsuperiorfilterassembly.

TheSeamMasterlineforbondingsyntheticsandnonwovens--aprocessthatcuts,"sews,"andsealsinjustonepass.

TheSureWeldlineforultrasonicplasticbonding--includinganoptionalmicroprocessor-controlledpowersupplythatcanbeattachedormountedseparately.

ThePhotovoltaic(PV)ModularSystemforsolarpanelassembly.

Plusalargeselectionofotherultrasonicbondingequipment.

Youcanpurchase,rent,orleaseSonobondultrasonicweldersandbondersasstand-aloneunitsorasmodularsystemsforintegrationintoyourproductionlineorcustomequipment.

Sonobondultrasonicequipmentisusedbyleadingmanufacturersintheautomotive,appliance,filtration,HVAC,apparel,aerospace,medical,electronic,electrical,photovoltaics,battery,andballisticvests/bodyarmorfields.Allmachineryisdependable,environmentallyfriendly,andeasytooperate.

Call13771501564toseeifyourapplicationcanbeimprovedusingSonobond'sultrasonicbondingtechnology.

Whenitcomestoultrasonics,Sonobondisthenametorelyon.

原本是针对塑料焊接设计的

高振幅,低振动力适用于塑料焊接(低阻抗)

震动垂直于焊接表面

必须转换90度才可以提供金属焊接所需的剪切运动

悬臂结构,力的作用点与焊接点有一定距离

必须旋转90度才可以提供剪切运动

震动是剪切模式,和焊接表面平行

受力直接作用于焊接点

低振幅,可变振幅以及高震动力适用金属焊接(高阻抗)

减少弯曲应力和停顿

作用力直接作用在焊头顶端,没有后倾现象

不用对换能器进行固定,换能器能量损失小

横向振动波,对被焊接工件表层损伤小

对于镀锡件,氧化件可进行直接焊接

焊头小,价格便宜,容易更换

焊接能力:Max.100mm2

WS2016,1.5kW/WS2026,2.5kW

无锡尼可超声波设备有限公司设立于江苏无锡市;无锡地处江苏省南部,是我国著名的“鱼米之乡”、长三角地区首屈一指的工业重城,贯通中国南北的京杭大运河在此交汇,中国最具活力城市之一。无锡尼可超声波占地面积5000多平方米,公司下属二个单位:无锡晨荣机械经营部和北京尼可超声波设备有限公司,公司现有工程技术人员占40%以上,大专以上文凭占60%。目前公司在超声波焊接领域处于领导地位,生产、研发的多款产品,其技术含量处于国内领先水平,我们的目标是打造世界一流的自动化超声波制造企业。

无锡尼可超声波-SonobondUltrasonics中国区域唯一正式代理商。

主要从事超声波应用和塑料技术研发,并与726声学研究所、江苏河海大学、哈尔冰理工大学等建立合作关系。并于2002年取得多项专利。

主要从事专用及重要设备的设计与研发,竭力为客户设计开发安全、新颖、先进节能的汽车零部件的生产设备。